Pet Flakes for Sale Price

| Quality: | Hot, Cold washed Without rings, without caps |

| PVC | Less than 100 PPM |

| Impurity | Less than 300 PPM |

| Super Clean Made Size | Less than 50mm |

| Moisture: | 1.3% |

| Color: | 100% clear |

| Application: | Stable fiber, sheets |

| Packing: | In 25/50 kg bags, jumbo bags or as required. |

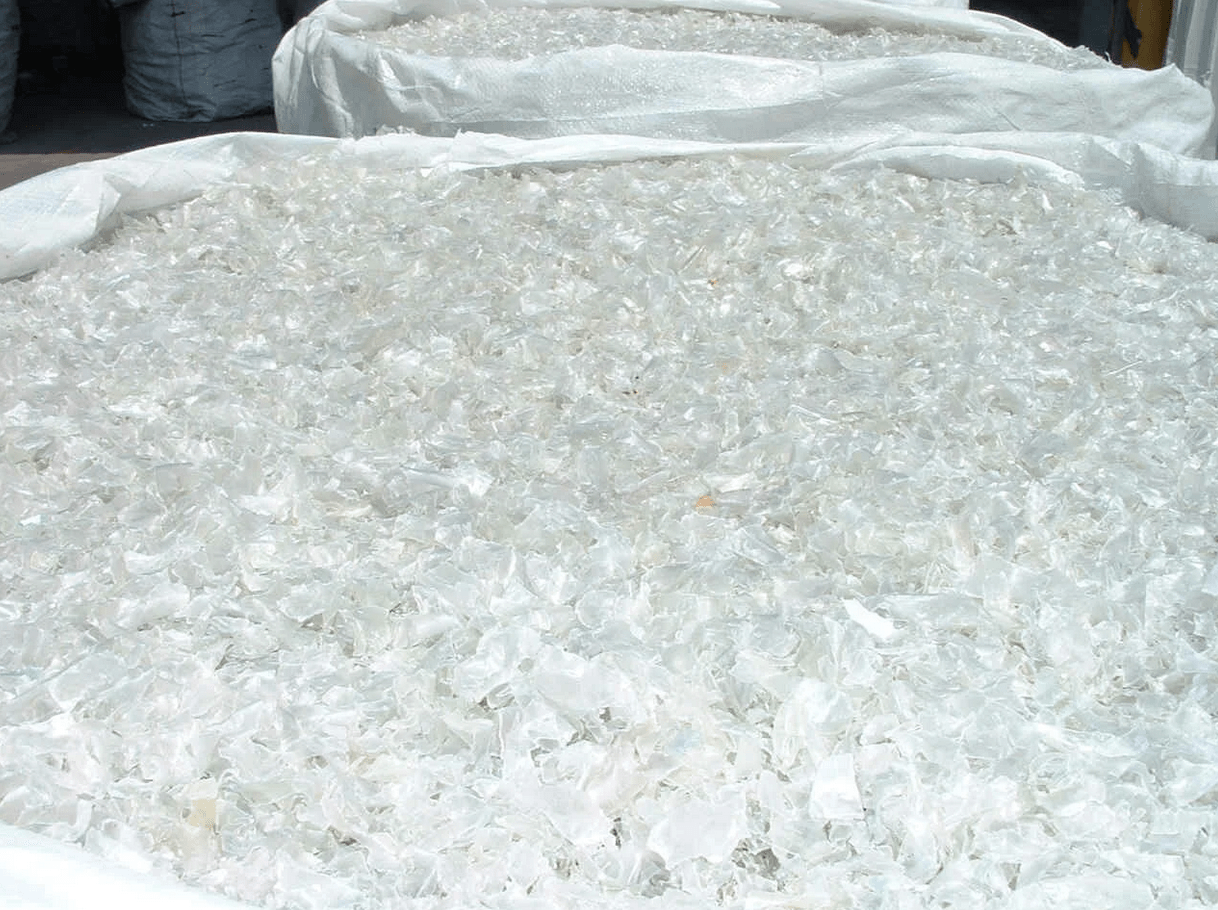

PET Bottle Flakes

PET bottle flakes are small fragments of PET bottles that are obtained through various procedures such as cutting and crushing operations . PET stands for polyethylene terephthalate, a type of plastic that is widely used in the production of bottles and other packaging materials . These flakes are manufactured from plastic bottles and can be sold or used in different applications .

Pet Flakes

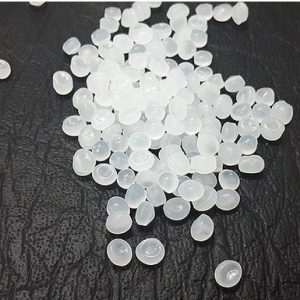

The uses of PET bottle flakes are diverse and include the manufacturing of new PET bottles, preparation of resin, and production of bristles in various industries . These flakes can be processed by blowing, injection, and other methods to create strong and lightweight materials . Some specific applications of PET bottle flakes include: – Making recycled PET bottles and food contact bottles – Production of pellets, granules, and resins for plastic production lines – Manufacturing of PET-pellets or flakes for bottle-to-bottle recycling and A-PET products

The importance of recycling PET bottles cannot be overstated, as they are highly sophisticated materials and are too valuable to be simply discarded in a bin . PET is 100% recyclable, which means it can be used to produce new products, reducing the environmental impact of plastic waste . Mechanical recycling of PET involves obtaining clean PET flakes that can be used directly or mixed with virgin polymer to produce new products . However, a key aspect of PET bottle recycling is the quality grade of the PET bottle flakes, which is crucial for the successful recycling of PET materials . Hot Washed Pet Bottle Flakes

Production and Quality of PET Bottle Flakes

The production process of PET bottle flakes begins with the collection and recycling of post-consumer PET bottles, which are then sorted and cleaned. Afterward, the bottles are crushed into small pieces, and impurities such as labels, caps, and other contaminants are removed. The PET flakes are further processed through various washing line equipment that utilizes friction washing, rinsing, flotation, and other steps to ensure thorough cleaning. This recycling process not only allows for the efficient reuse of PET material but also helps mitigate the environmental impact of plastic waste disposal. Scrap Metal Trader

Several factors contribute to the quality of PET bottle flakes. First and foremost, utilizing high-quality raw materials is essential for producing superior PET flakes. Additionally, controlling moisture content is crucial, as high moisture levels can negatively impact the quality and marketability of the flakes. To overcome this issue, manufacturers should implement effective drying processes during the production stage. Furthermore, adhering to stringent quality control measures and industry standards will help ensure the production of high-quality PET flakes. Some key factors affecting the quality of PET bottle flakes include: – Quality of raw materials used – Moisture content within the flakes – Adherence to industry standards and quality control measures

Hot Washed , Cold Washed Pet Bottle Flakes

There are numerous benefits of using PET bottle flakes for various industries. One of the primary uses of cleaned and dried PET bottle flakes is in the production of polyester staple fiber, which can be used to create a wide range of materials and products. PET is a recyclable solution that offers performance benefits not found in alternative packaging options, such as glass bottles and aluminum cans.

Moreover, PET flakes are utilized for recycling due to their high purity and quality, making them ideal for producing new bottles. By recycling PET bottles, valuable resources are saved, and waste is reduced. Furthermore, using recycled PET flakes promotes sustainability by decreasing the consumption of virgin materials and encouraging a circular economy approach to waste management.

Bennie Schmidt –

Reliable supplier of plastic scrap, providing us with materials that consistently meet our specifications. Their commitment to sustainability is reflected in their product line.